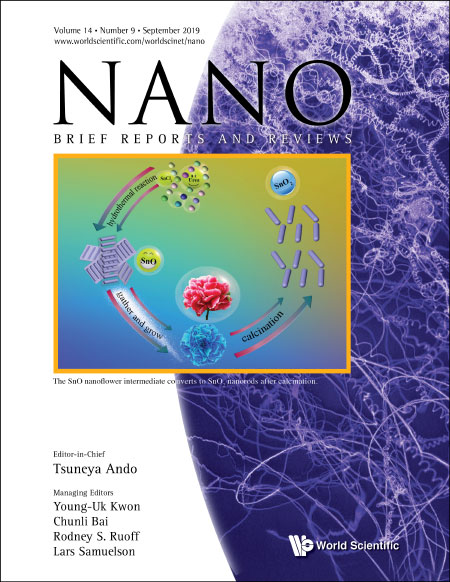

Hydrothermal Synthesis of SnO2 Nanorod as Anode Materials for Lithium-Ion Battery

Abstract

In this study, SnO2 nanorods are successfully prepared by simple template-free hydrothermal method without surfactant. SnO intermediate with lamellar morphology is first formatted by hydrothermal method and SnO2 nanorods are obtained after calcinations. The results of XRD characterization show that lamellar structured SnO intermediate has preferred orientation in 0 0 1 direction. According to supposed mechanism during formation process of SnO2 nanorods, tiny crystal nucleus of Sn(OH)2 and a bit of SnCO3 are generated from SnCl2 and urea. Then the crystal nucleus gather together to form a nanorod. With continued reaction, nanorods gather together to form sheets and the sheets grow up to lamellar morphology and the intermediate decomposes into SnO because of the hydrothermal process. The SnO intermediate convert to SnO2 with sheets breaking to nanorods after calcination. The results of galvanostatic cell cycling show that SnO2 particle has high specific discharge capacity capacity. This experiment of SnO2 nanorod preparation provides us an effective way of easy processing, low cost, and more environmentally synthesis strategy to synthesize SnO2 nanorods.