Abstract

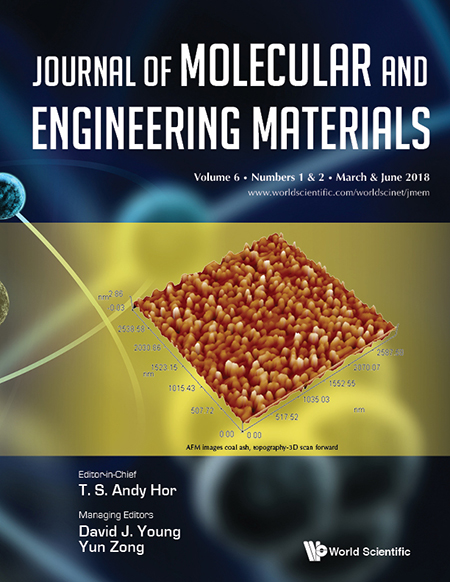

In this study, coal ash/recycled plastic composite material was fabricated with post-consumer high-density polyethylene (HDPE) and coal ash particles. The main idea of using coal ash, since it is also a waste product, as reinforcing filler in recycled HDPE is to reduce the cost, develop lightweight and produce environmental-friendly materials. Coal ash/recycled plastic composite have been used in significant applications as construction materials including flooring, landscaping, fencing, railing window framing and roof tiles. Effect of coal ash loading on the mechanical properties and thermal conductivity of coal ash/recycled HDPE composite were determined. It is expected to use waste materials in new field by getting novel composite materials with developed mechanical properties. It was found that coal ash filler indicated significant improvement on the mechanical properties of composites. The results show that the impact decreased tremendously from 57.32 to 15.8kJ/m2 with only 30wt.% loading of coal ash. The filler increases the elasticity of the material and reduces its ability to absorb deformation energy.