Refractive index characteristics of edible oils based on spectrometry and effects of oil dispersion on OCT

Abstract

It is necessary to investigate the wavelength-dependent variation rules of the refractive index of edible oils so as to explore the specificity of the dispersion in light propagation, imaging, and interference processes among different types of edible oil products. In this study, by deriving the refractive index equations of the double glass sheet holding device and oil, the reflectance spectra of three different types of oil samples, namely, peanut oil, colza oil, and kitchen waste oil, were measured via a spectrometer. Furthermore, the refractive index model of these different types of oil samples was investigated. Additionally, based on the oil dispersion characteristics, the dispersion of oil in optical coherence tomography (OCT) was compensated via deconvolution. In the wavelength range of λ∈ (380, 1500)nm, the analytical expressions of the double glass sheet holding device and oils are featured by practical reliability. The refractive indexes of three different types of oils n∈ (1.38, 1.52) show normal dispersion characteristics. The Cauchy coefficient matrix of the oil refractive index can be used for oil identification; in particular, the healthy oil and waste oil differ significantly in terms of the Cauchy coefficient matrix in the infrared band. Oil dispersion has almost no influence on the phase spectra of oils but can enhance their amplitude spectra. The dispersion mismatch can be eliminated by calculating the convolution kernel. The envelope broadening factors of OCT interference signals of oil products are 0.84, 0.64, and 0.91, respectively. According to the present research results, the refractive index model of oil can effectively remove the influence of the holding device. The refractive indexes of three different types of oil samples show similar wavelength-dependent variation characteristics, which confirms the existence of many correlated components in these oil samples. The established refractive index model of oil in a wide spectral range, from the ultraviolet to the infrared band, can be adequately employed for identifying different types of oils. The numerical dispersion compensation based on the established refractive index model can enhance the axial resolution in OCT imaging.

1. Introduction

Safety detection is particularly important for edible oils.1 Currently, common techniques for edible oils and the finished products mainly include conventional physical and chemical detection, chromatography, nuclear magnetic resonance identification, and spectroscopy. However, due to the lack of effective detection systems and standards, researchers have gained insufficient knowledge regarding oil dispersion characteristics and related detection using the existing optical methods, such as Fourier transform-infrared (FT-IR) spectroscopy,2 biomass spectrometry,3 low-field NMR,4 and Terahertz spectroscopy.5

Researchers generally use the Cauchy equation for accurately characterizing the dispersion relation of biological material.6 With regard to edible oils, only Chengchao et al. from the Harbin Institute of Technology performed the characterization of wavelength-dependent refractive index variation rules of both colza oil and peanut oil using the Cauchy equation via double light path transmission.6,7 According to their results, the refractive index of colza oil at 632.8nm was 1.5197; however, they did not examine waste oil, and different types of oils exhibit no specificity. Zhang et al.8 from the University of Shanghai for Science and Technology employed light interference fast measurements on different oils at room temperature, with a wavelength of 632.8nm. Through these measurements, the refractive indexes of the Luhua 5S first-grade pressing peanut oil and the Duoli highly flavored colza oil were found to be 1.4709 and 1.4718, respectively. Overall, the measured refractive indexes of different types of oils in previous studies were poor in regularity and restricted in the narrow visible wavelength range, thereby providing less support for oil identification.

In this study, the reflectance spectra of colza oil, peanut oil, and kitchen waste oil were measured using a spectrometer to investigate the variation characteristics of the oil refractive index with wavelength. Moreover, the dispersion characteristics of various types of edible oils were accurately characterized via the Cauchy equation. In contrast with the double light path transmission method, the present method exhibits high precision and is more convenient in operation.6 In addition, the Cauchy refractive index matrices of different types of oils show a significant difference. On this basis, the dispersion compensation of oil during the imaging process was investigated by means of optical coherence tomography (OCT), and the dispersion mismatch of the sample was eliminated by calculating the convolution kernel, thereby effectively enhancing the axial resolution of OCT.

2. Experiment

2.1. Experimental samples and holding device

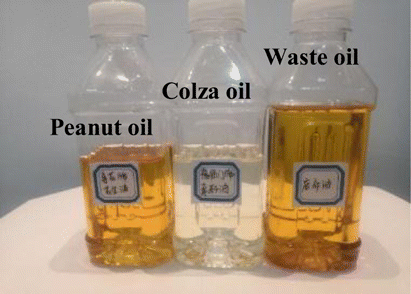

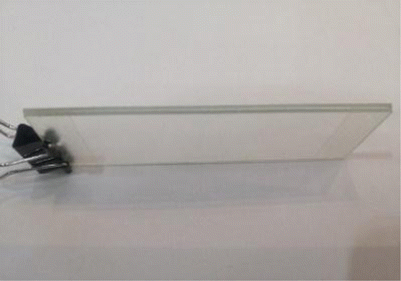

In this study, three different types of edible oils, namely, colza oil (nongenetically modified organism (non-GMO) first-grade colza oil from Fulinmen Company), peanut oil (5S pressing first-grade peanut oil from Luhua Company), and kitchen waste oil (Luhua peanut oil that was fried several times), as shown in Fig. 1, were measured. The holding device consisted of two layers of microscope slides with a thickness of 1.2mm. The two slides were glued in parallel with a spacing of 0.0615 mm, as shown in Fig. 2.

Fig. 1. Experimental samples.

Fig. 2. Double glass sheet holding device.

2.2. Experimental instrument

The spectra were measured using a LAMBDA950 ultraviolet-visible-infrared spectrometer manufactured by the PERKINELMER Company with a wavelength range of 175–3300nm (380–1500nm was used in this study). In particular, the bandwidth of the resolution is 0.05nm, the wavelength precisions are ±0.08nm and 0.30nm in UV/VIS and NIR ranges, respectively, the wavelength repeatability is below 0.005nm, and the baseline flatness is below 0.0008A. A deuterium lamp serves as the light source in the wavelength range of 175–319.2nm, while a halogen lamp serves as the light source in the wavelength range of 319.2–3300nm. All optical devices adopt a total reflection circuit arrangement so as to effectively eliminate wavelength discrimination. A double-beam integrating sphere was arranged in the instrument, whose inner diameter and wavelength range are 150mm and 200–2500nm, respectively.

2.3. Experimental methods

First, different oil samples (colza oil, peanut oil, and kitchen waste oil) were added to the double glass sheet holding device for quiescence. Next, in order to achieve a baseline calibration, the spectrometer was preheated for 5min. Finally, the double glass sheet holding devices with different oil samples were placed inside the sample chamber of the spectrometer. During the whole scanning process, the light beam was kept at vertical incidence, and the reflectance spectra in the wavelength range of 380–1500nm were selected for further analysis.

3. Holding Device and the Refractive Index Model of Oil

3.1. Theoretical analysis of the refractive index of the double glass sheet holding device

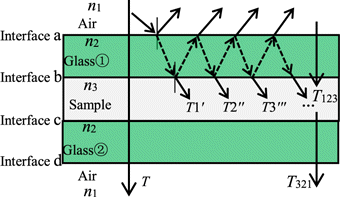

As shown in Fig. 2, a certain air gap was presented between two glass sheets for holding the sample. Figure 3 displays the light paths of the device.

Fig. 3. Light paths of the double glass sheet device.

3.1.1. Air–glass sheet ① — sample transmission process

n1, n2, and n3 are the refractive indexes of air, the glass sheet, and the sample, respectively. The single reflectivity at interface a and the single reflectivity at interface b are denoted as R1 and R2, respectively. T1 and T2 are the single transmissivities at interface a and interface b, respectively; T denotes the total transmissivity of the double glass sheet holding device measured via the spectrometer; T1′ denotes the transmissivity of the transmission light from interface b after passing through interface b for the first time; T2′′ denotes the transmissivity of the transmission light from interface b after passing through interface b for the second time; T3′′′ denotes the transmissivity of the transmission light from interface b after passing through interface b for the third time. The sum of the transmissivity when the light passes from a medium with a refractive index of n1 to a medium with a refractive index of n3 is denoted as T123. The sum of the transmissivity when the light passes from a medium with a refractive index of n3 to a medium with a refractive index of n1 is denoted as T321.

According to the electromagnetic wave propagation theory.9 In the case of vertical incidence, the reflectivity can be written as

3.1.2. Air–glass sheet ② — sample transmission process

Similarly to the analysis in Sec. 3.1.1, T321 can be written as

3.1.3. Analytic relationship between the refractive index, the transmissivity, and the reflectivity

The upper part of the sample is composed of air and the glass sheet, while the lower part of the sample is composed of the glass sheet and air. The two glass sheets are composed of the same material. Accordingly, the absorption of light by the glass sheet and air can be neglected. According to the derivation process of Eq. (3), the following expression can be obtained :

First, assuming that air is the sample, then n3=1. By substituting n3=1 into Eq. (2), it can be obtained that R1=R2 and T1=T2. Next, the following expression can be derived by combining Eqs. (3) and (6) :

By combining Eqs. (3) and (6), the following expression can be obtained :

3.2. Experimental results of the refractive index

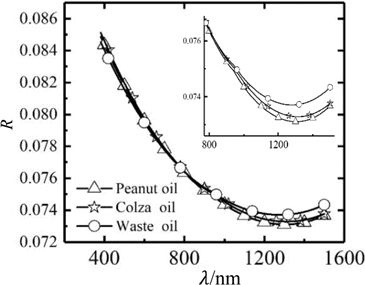

The reflectivity of the double glass sheet holding device and the total reflectivity when different oil samples were placed in the holding device were measured via the spectrometer, as shown in Figs. 4 and 5, respectively.

Fig. 4. Reflectivity of the double glass sheet device.

Fig. 5. Reflectivity of the three different types of oils in the double glass sheet device.

As shown in Fig. 4, the reflectivity of the double glass sheet holding device in the wavelength range of 380–1500nm decreases with the increase of the wavelength. It can also be observed from Fig. 5 that the reflectivity of the three different types of oil samples in the holding device drops as the wavelength increases in the range of 380–1500nm.

The three different types of oil samples are highly similar in reflection characteristics, which indicates similar states of three samples, as well as the existence of many identical or highly correlated components. In addition, the variation of the reflectivity for the three oil samples with the wavelength also differs slightly. Moreover, the reflectivity also includes the reflection information of the holding device. The reflection characteristics of the oil sample should be extracted and the difference among different oil samples should be highlighted.

3.3. Reflective index of the glass sheet

By replacing T in Eq. (7) with T=1−R, the following expression can be obtained :

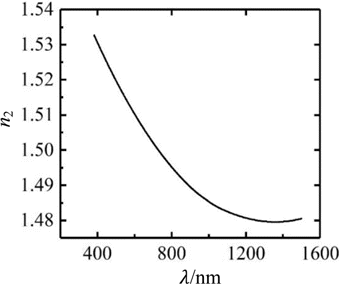

Fig. 6. Refractive index of the glass sheet.

Therefore, Eqs. (9) and (12) describe the mathematical model of the refractive index of the glass sheet in an analytical format, and Fig. 6 shows the corresponding numerical results. Evidently, the refractive index of the glass sheet decreases with the wavelength in the range of 380–1500nm (n2∈ (1.4806, 1.5329)).

Guozhong et al. employed the thickness transmission method for exploring the variation characteristics of the refractive index of the glass sheet with the wavelength in the range of 300–600nm.10 In this study, the variation of the refractive index of the double glass sheet holding device with the wavelength in a broader range of 380–1500nm was investigated via reflection. Table 1 compares the present results with the refractive index measured in Ref. 10.

| Wavelength (nm) | This article n | Literature10n | Relative deviation (%) |

|---|---|---|---|

| 380 | 1.5329 | 1.54 | 0.46 |

| 400 | 1.5306 | 1.52 | 0.69 |

| 420 | 1.5283 | 1.53 | 0.11 |

| 440 | 1.5261 | 1.52 | 0.40 |

| 460 | 1.5239 | 1.52 | 0.26 |

| 480 | 1.5218 | 1.52 | 0.12 |

| 500 | 1.5197 | 1.51 | 0.64 |

| 520 | 1.5178 | 1.51 | 0.52 |

| 540 | 1.5158 | 1.52 | 0.28 |

| 560 | 1.5139 | 1.50 | 0.93 |

| 580 | 1.5121 | 1.51 | 0.14 |

It can be observed that the relative deviation of the refractive index measured in the present study with respect to the result in Ref.10 is within the range of (0.11%, 0.93%), indicating a good level of agreement. In other words, the established refractive index model based on the spectrometer is reliable. As also shown in Table 1, the present refractive index model successfully overcomes the limitation of the narrow wavelength range and shows strong regularity in a wide wavelength range of 380–1500nm.

The relative deviation in Table 1 can be mainly attributed to the difference of the glass sheet material, experimental environment, instrument, and device precision. More specifically, the precision difference led to different significant digits of the data.

3.4. Refractive index of oil

By replacing T in Eq. (10) with T=1−R, it can be derived that

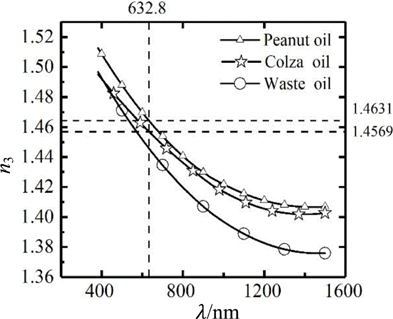

Fig. 7. Refractive index of oil.

Evidently, the refractive index of oil decreases as the wavelength increases in the range of 380–1500mm, which is in good agreement with the conclusions in Ref. 7. This also suggests that many identical or highly correlated components exist among different types of oil samples. The reflective indexes of the three different types of oil samples exhibit significant specificity, and especially a great difference in the infrared range. The normal oil can be easily distinguished from the waste oil, which can provide theoretical foundations for establishing an oil identification system in the infrared wavelength range.

As described in Ref. 7, the holding device mainly consists of two pieces of optical glass. The variation of the refractive index of the optical glass with the wavelength was ignored in calculating the refractive index of oil, and the refractive index of the optical glass was set to an average value (n=1.52); all these assumptions inevitably led to an inaccurate refractive index of oil. In this study, the characteristic function of the refractive index of the holding device with the wavelength was first investigated and then applied to the analysis of the refractive index of oil. Therefore, the conclusion regarding the refractive index of oil is more noteworthy and accurate than the results in Ref. 7.

In this study, the refractive indexes of the Luhua 5S pressing first-grade peanut oil and the Fulinmen colza oil at 632.8nm were 1.4631 and 1.4569, respectively. The relative deviation between the present value of the Luhua first-grade peanut oil and the value using optical interference rapid measurement8 was only 0.53%.

3.5. The Cauchy equation of the refractive index of oil

The decreasing functions, as presented in Fig. 7, are indicative of a normal dispersion for the three types of oil samples. With regard to these bio-samples, the dispersion relation n=n(λ) can be accurately characterized by the following Cauchy equation :

where A, B, and C remained unchanged and are referred to as the Cauchy coefficients. By substituting the corresponding data of Fig. 7 into Eq. (14), the Cauchy coefficient matrices of the peanut oil sample, the colza oil sample, and the kitchen waste oil sample can be calculated using the method of undetermined coefficients, as shown in Table 2.

| Sample | A | B | C |

|---|---|---|---|

| Peanut oil | 1.38808 | 0.03752 | −0.00299 |

| Colza oil | 1.38216 | 0.03850 | −0.00351 |

| Waste oil | 1.35464 | 0.04601 | −0.00395 |

Table 2 shows the Cauchy coefficients of the refractive indexes of the different types of oil samples. The Cauchy coefficients of three different oil samples show applicable and operable distinction points. In particular, the kitchen waste oil and the healthy oil differ significantly. Therefore, an effective index system for oil identification is expected to be developed by utilizing the specificity of the Cauchy coefficients of various types of edible oils.

4. Effect of Oil Dispersion on OCT

As described in Secs. 3.4 and 3.5, oil shows distinct dispersion characteristics, and various types of oils differ in dispersion characteristics. During OCT imaging process, the dispersion characteristics of oils and the optical elements in the imaging system can cause the envelope broadening of the optical coherent signal, thereby reducing the axial imaging resolution.11

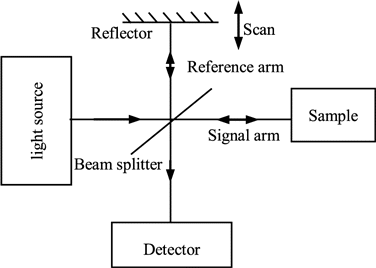

4.1. Analysis of OCT dispersion characteristics

As shown in Fig. 8, the Michelson interferometer is the key component in OCT.12 The light from a low-coherence source can be split into two light beams via the beam splitter, in which one beam is the reference light and the other beam is the signal detection light. The former reference beam is reflected by the reflector, then passes through the reference arm, and finally arrives at the detector. The latter detection beam is first scattered by the sample and arrives at the detector after passing through the signal arm. The signal light beam of the signal arm is interfered with the reference beam of the reference arm and finally received by the detector.13,14

Fig. 8. Schematic diagram of the OCT imaging process.

By ignoring the DC term, the interference signal in the frequency domain received by the detector can be expressed as15,16

where In(k) denotes the scattering intensity of the nth layer of the sample, Re is the real part, k = 2π/λ denotes the wave number (WN), Ir(k) denotes the light intensity returned from the reflector, ϕ(k, zn) denotes the phase difference of the nth layer of the sample relative to the reference light, and ΔZn denotes the light path difference of the nth layer of the sample relative to the reference arm mirror. ϕ(k, zn) can be written as

where nn denotes the effective refractive index of the nth layer of the sample, ng,n denotes the effective group refractive index of the nth layer of the sample, the third item denotes the second-order dispersion at the center frequency or the group delay dispersion per unit length, and the fourth item is referred to as the third-order dispersion per unit length. The third-order and the higher-order items are referred to as the dispersion items. According to Eq. (17), the second-order dispersion compensation coefficient a2 can be written as

4.2. Deconvolution of numerical compensation for oil dispersion in OCT

Since the interference signal received by the CCD is a real rather than complex signal, the Fourier transform of the signal may produce a complex conjugate.18 Therefore, the interference signal should undergo a Hilbert transform in order to acquire the phase spectrum of the interference signal. The oil-depth-dependent convolution kernel can then be solved based on the oil dispersion characteristics, and the dispersion mismatch induced by the sample dispersion can be eliminated through the convolution operation. Finally, the interference signal after dispersion compensation can be obtained using a fast Fourier transform. The above convolution kernel can be expressed as

Other characteristic parameters of the OCT system are linear array InGaAs detector, A-Scan frequency is 1.2kHz, imaging sensitivity is not less than 105dB, axial resolution of u1∕2 in the air is <7.0μm, radial resolution is 8μm, maximum imaging depth is 1.7mm, maximum resolution is 512 pixels, maximum scanning speed is 2 frames/s, visual field is 10mm×10mm×1.7mm.

4.2.1. Phase and amplitude spectra of oils

In the OCT system, by ignoring the DC item, the light current component produced by the light interference signal can be written as19,20

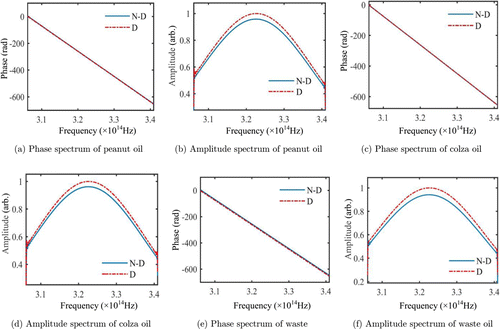

As described above, after performing the Hilbert transform and the Fourier transform on the interference signal, the frequency spectra of the peanut oil, the colza oil, and the kitchen waste oil (namely, the phase spectra and the amplitude spectra) can be obtained, as shown in Fig. 9.

Fig. 9. Phase and amplitude spectra of the three oils.

Figure 9 shows the phase and amplitude spectra of the three different types of oil samples. In this figure, the N-D curves denote the signal without dispersion (corresponding to ideal conditions), while the D curves denote the signal before dispersion compensation.

By observing the results in Fig. 9, the following considerations can be made:

| (1) | The three types of oils show almost the same phase spectra and very similar heights in the amplitude spectra, which can be mainly attributed to similar Cauchy dispersion characteristics of the three oils and similar introduced dispersion factors. | ||||

| (2) | The phase curves of the three different types of oils with and without dispersion are almost coincident with each other. Since the refractive index of the oil shows no obvious change with the wavelength in the range of λ∈(902.74,957.26)nm, i.e., the dispersion is weak, the phase spectra with and without dispersion differ slightly. | ||||

| (3) | The amplitude spectra of the three different types of oils are gradually axisymmetric. By taking the right side of the symmetry axis as an example, the difference of the amplitude spectra with and without dispersion decreases with increasing frequency. Since the introduced dispersion factor imposes a decreasing effect on various high-order items, the effect of the second-order dispersion item is mainly taken into account in dispersion compensation, while the effects of the third-order and higher-order items can be ignored. | ||||

| (4) | By comparing the three amplitude spectra in Fig. 9, it can be easily observed that the N-D curves are always lower than the D curves, which suggests that the amplitude spectra of the interference signal drop to a certain degree without dispersion or after dispersion compensation. This reduction can be used at the expense of an increase in the axial resolution. If the effect of dispersion compensation on the OCT imaging depth is taken into account, the decrease in the amplitude spectra of the interference signal may reduce the imaging depth. Additionally, the increase of the axial resolution may increase the imaging depth. Overall, the dispersion compensation mechanism can impose bidirectional effects on the imaging depth; thus, an equilibrium state can be found. | ||||

4.2.2. Comparison of the interference signals before and after dispersion compensation

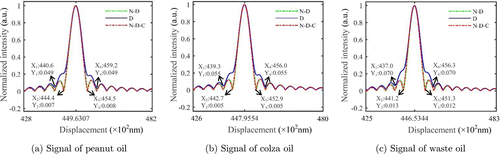

Based on the obtained dispersion characteristics of three different types of oil as described in Sec. 3.5, dispersion compensation was performed on the interference signals of different oils in OCT using the deconvolution algorithm, as shown in Fig. 10.

Fig. 10. Envelope of interference signal before and after dispersion compensation of three edible oil samples.

Figure 10 shows the envelope of interference signal before and after dispersion compensation of three edible oil samples. In this figure, the N-D curve, the D curve, and the N-D-C curve represent the signals without dispersion (in the ideal case), before, and after dispersion compensation, respectively.

In Fig. 10, the x-axis and y-axis denote the displacement of the signal arm at zero light path difference and the light intensity, respectively. The displacement L can be expressed as

By observing the results in Fig. 10, the following considerations can be made:

| (1) | Assuming that the thickness of the oil is 300×102 nm, the characteristic displacements of the signal arm for the three different types of oils under zero light path difference are 449.6307×102nm, 447.9554×102nm, and 446.5344×102nm, respectively, suggesting different dispersion characteristics among different oils. Additionally, since the light path equals the product of the refractive index and the distance, the characteristic displacement of the signal arm in OCT can serve as the potential index of oil identification. | ||||

| (2) | The interference signals of the three different types of oils before dispersion compensation show envelope broadening to varying degrees. First, the first minimum value of signal intensity in Fig. 10 is marked by the data moving mark function of MATLAB software, which has four points in total. Secondly, f was supposed to be the axial signal broadening factor and defined as f=[(x4−x1)−(x3−x2)]/(x3−x2). Therefore, taking peanut oil as an example, the calculated result can be expressed as f = [(459.2−440.6)−(454.5−444.4)]/(454.5−444.4)=0.84. Similarly, the calculated f values for colza oil and waste oil are 0.64 and 0.91, respectively. | ||||

Evidently, the signal broadening significantly drops after dispersion compensation, and the signal after dispersion compensation is almost coincident with the interference signal without dispersion. Therefore, given the dispersion characteristics of the oils, the dispersion of the OCT system can be compensated via deconvolution to enhance the axial resolution.

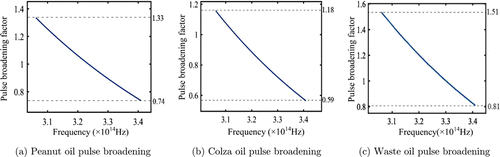

4.2.3. Pulse broadening induced by oil dispersion

Since the propagation speed of light in the dispersive medium is connected with the frequency and the refractive index, the pulse signals of the light during the propagation through media with different refractive indexes show different phase delays, finally resulting in pulse broadening to different degrees. Figure 11 shows the pulse broadening results of three different types of oil samples.

Fig. 11. Pulse broadening of three oil products.

It can be observed that at a frequency of 3.05×1014–3.4×1014Hz, the pulse broadening factors of the peanut oil sample, the colza oil sample, and the waste oil sample are in the ranges of 1.33–0.74, 1.18–0.59, and 1.51–0.81, respectively. These values are in good agreement with the above-mentioned envelope broadening factors of OCT interference signals induced by oil dispersion 0.84, 0.64, and 0.91.

5. Conclusions

The behavior of the refractive index with varying wavelength and the spectral characteristics of three different types of oil samples (peanut oil, colza oil, kitchen waste oil) are very similar, indicating the existence of many correlated components in different oils. However, the refractive index Cauchy matrices of the three different types of oils show distinct differences. Accordingly, the mathematical model for the oil refractive index in a broad wavelength range λ∈(380,1500)nm overcomes the limitations of the existing research results, such as roughness and narrow waveband, and exhibits a series of advantages, including high precision and strong general applicability. Moreover, the effect of the specific holding device can be eliminated so as to effectively highlight the specificity among different types of edible oil products. Therefore, the refractive index model and the Cauchy matrix are appropriate as effective indexes for oil identification.

Based on the dispersion characteristics of different oils (i.e., the mathematical model of the refractive index), dispersion compensation was performed on the OCT system via deconvolution, which can effectively enhance the axial imaging resolution and simultaneously reduce the amplitude spectra of the interference signal. These two results cause opposite effects on the OCT imaging depth. The present study can provide theoretical foundations for extracting different dispersion compensation parameters from different oil products in OCT experiments. Both the characteristic displacement of the signal arm in dispersion compensation and the dispersion-induced pulse broadening factors can serve as potential indexes for oil identification.

Conflict of Interest

The authors declare that there is no conflict of interest relevant to this article.